Collaboration with RMIT at AMP

Early this year we were approached by RMIT to take part in a new program involving education, technology and manufacturing. In particular we agreed to collaborate with RMIT on a public sculpture that would include student participation and utilise the world-class teaching facilities at RMIT’s AMP (Advanced Manufacturing Precinct).

Program Manager Michael Fuller invited Chris from Lump to view the new facilities and machinery at RMIT ‘s AMP and discuss the exciting proposal. The brief proposed a collaborative project whereby students formally contribute to artistic discussions and designs in relation to the overall aesthetic finish applied to a sculpture. The sculpture, being a piece designed and manufactured by our very own Lump team. The students apply their designs using 3D CAD Modeling software and wrap their concepts onto the surface of the sculpture in preparation for 3D laser cutting.

All of us at Lump were super excited to get on board this project and Michael arranged for the RMIT student group to visit Lump Studio. Here they could gather a thorough understanding of our existing manufacturing capacities and processes. And it would give them a tangible idea as to where they themselves and their concepts slot into the highly technical parts of the project outside of the university.

With many interested parties contributing to the program, Michael facilitated a platform on Basecamp.com a website that specialises in project management software. This platform easily keeps everyone involved and in the loop and also encourages constant feedback and interaction between all involved.

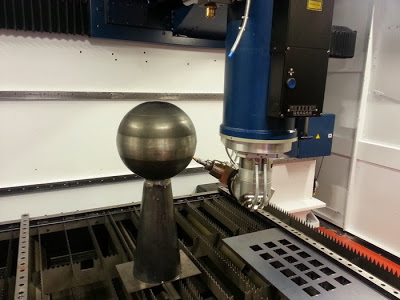

Once the partial fabrication of the initial sculpture was completed at Lump Studio, the absolute final measurements were taken and files were created ready for the students to three-dimensionally wrap the sculpture with their design concept. One student had their design selected to feature on the sculpture which was 3D Laser Cut into the piece using the new world class 3D Laser Processing Center at RMIT’s Learning Factory at the AMP.

The sculpture transformed by this incredible opportunity is “Jacks”, designed and made at Lump HQ especially for the collaboration. The concept for the piece is to explore familiar forms through future focused technology and mean. The form itself is a representation of the future remaking an object from the past.

Using high tech materials and manufacturing our sculpture evokes the familiarity of the Jack. The Jack being the main playing component used in the schoolyard game we used to call “Jacks” or some may know it as “knuckles”. By remaking the Jack in a modern form such as this, we hope to imbue a meaning of balance and positivity while remembering and connecting with a moment in the past.

One of the great things about being involved in the Learning Factory at the AMP is witnessing first hand the commitment that RMIT’s AMP is extending to the future of Australian Manufacturing through education involving design, technology and manufacturing. And all of us at Lump have been very proud to play a tiny little role in that through this program.

At Lump we are committed to creating original designs and producing and manufacturing our work in Australia. And the recent engagement between Lump and AMP of RMIT within the Learning Factory Model has been invaluable to furthering our own industry education and the building of the industry knowledge bank the entire crew shares at Lump.